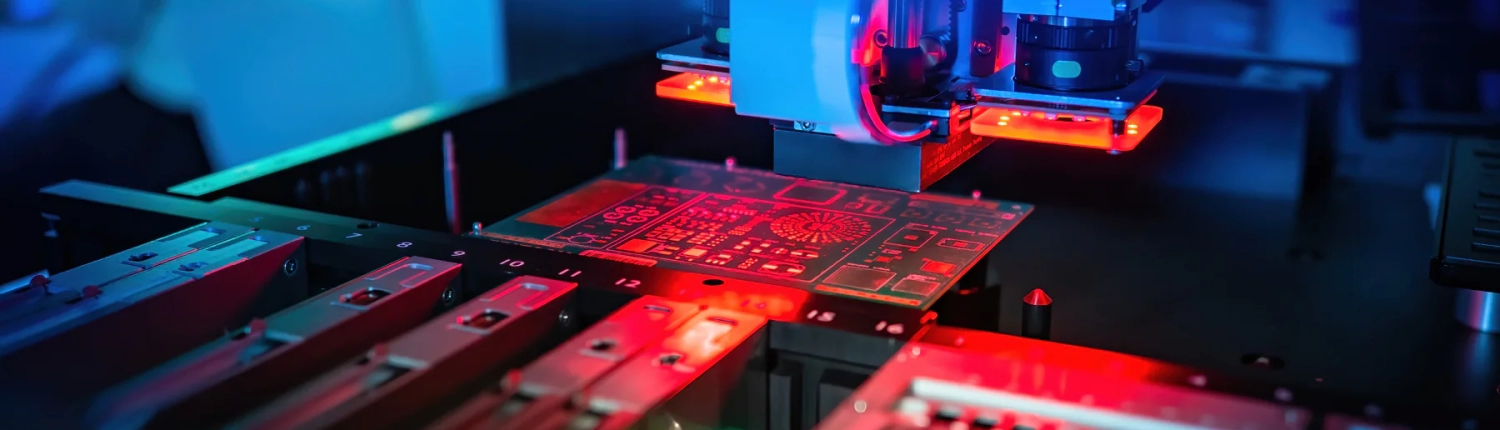

Light-Curable Materials for Print Circuit Board Assembly

Hanarey offers a broad range of light-curable materials for use in circuit protection and electronic assembly applications. These materials cure in seconds for faster processing and higher throughput and are available with many innovative and patented technologies that turn problems like shadow areas, cure confirmation, and difficult inspection into non-issues.

The materials are electrically insulating, making them a perfect fit for conformal coating, encapsulation, bonding, thermal management, masking, and many other electronic assembly processes. Hanarey light-curable materials are one-part materials, no mixing or preparation is required before application.

Features

Excellent adhesion to a variety of substrates

Cure with LED, UV, or visible lights in seconds

One component, no mixing required

Solvent free