FE-225 LED Flood-Curing System

High-Intensity, Large Area System for Speed, Depth, and Fullness of Cure

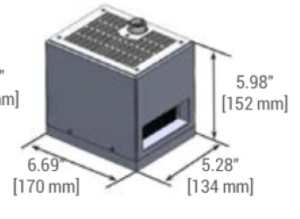

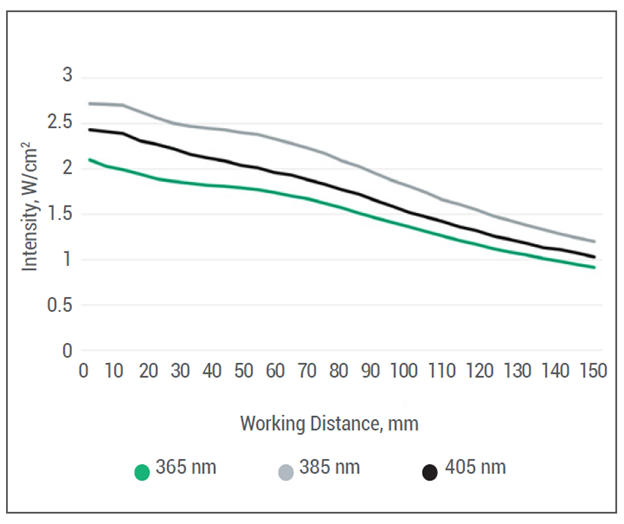

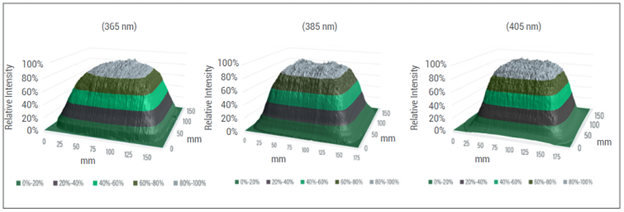

The FE-225 is a high intensity flood-curing system that delivers true, high-irradiance LED light for high speed, depth, and fullness of cure. For the user who needs to flood cure a large area, this system provides the best cure by combining intensities of over 2 W/cm² with a 5” x 5” (127 mm x 127 mm) curing area and high uniformity.

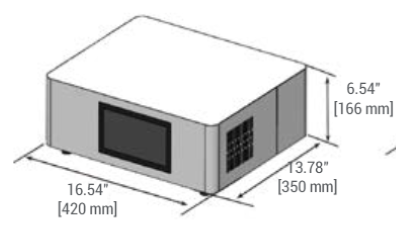

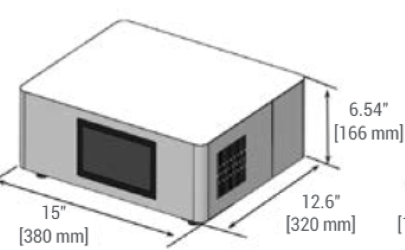

The FE-225 is comprised of a controller and up to two LED emitters. The controller features a 7” touch screen with an intuitive, easy to use interface. It can be activated, controlled, and remotely monitored by PLC, and also store programs and parameters for repeatable processes. The controller also continuously monitors the health of the emitters and controller, and reports faults directly to the controller screen.

A single controller can operate up to two emitters to save on cost and space. Extra emitters can be used to increase the area of light delivery or to use multiple wavelengths to extend application flexibility. Users will also appreciate the enhanced quality of life provided by our quiet, efficient operation. A variable speed fan keeps noise to a minimum, while also minimizing heat emission.

System Configuration

The FE-225 offers maximum flexibility as it can be coupled with a full suite of accessories and used as a bench-top system or be integrated into conveyors and larger machines.

Features